Product Descriptions

FIM-7L Pump and Tank Automation Control Unit

Next-generation control for Fuel and AdBlue management

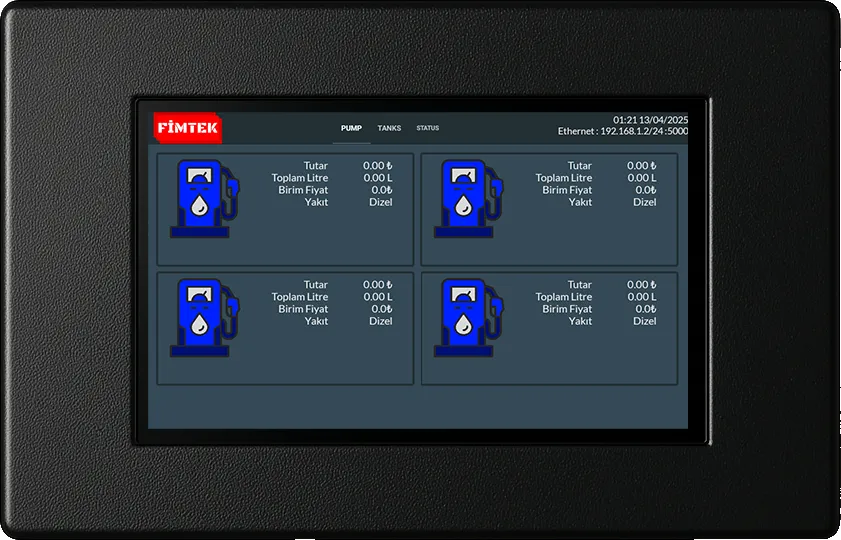

FIM-7L is an intelligent and powerful automation solution designed for modern fuel and AdBlue systems. With its 7” touchscreen, it allows you to easily manage all tank and pump operations from a single point. Its user-friendly interface provides a simple and intuitive experience for both field operators and administrators.

Full control with intuitive touchscreen

The high-resolution 7” HMI display lets you monitor all data in real-time. Tank levels, pump statuses, filling information, and alarm notifications can be easily tracked on a single screen. Its intuitive menu structure allows users to operate the system effortlessly without any technical knowledge.

Powerful hardware, reliable performance

At the heart of the FIM-7L lies a high-performance ARM-based processor. This powerful platform ensures fast and secure data processing. With its metal body and industrial design, it withstands harsh field conditions. It operates reliably in environments ranging from −20 °C to +60 °C, providing confidence in every situation.

Wide communication and integration options

Thanks to RS485, RS232, Ethernet, and 4G GSM support, the FIM-7L easily integrates with any field system. It is compatible with many pump and probe manufacturers through Modbus RTU/TCP protocols. This allows you to deploy the system without changing your existing infrastructure.

Real-time monitoring and centralized management

With FIM-7L, you can monitor tank levels, temperature values, and alarm conditions in real-time. Pump refueling operations, user logins, and vehicle-based fuel consumption are all recorded in detail. All data is securely transmitted to a central server and can be accessed remotely through a web-based management panel.

Remote access and software updates

FIM-7L stays connected with you not only on-site but also remotely. With its web-based interface, you can monitor system status from anywhere in the world and perform software updates easily via OTA (Over The Air). This feature accelerates maintenance processes and minimizes operational interruptions.

Intelligent alarm management

When tank levels reach critical thresholds, water levels rise, or pump malfunctions are detected, the system instantly alerts you through the integrated buzzer and programmable relay outputs. This allows you to detect potential risks before they escalate and maintain your operational continuity.

Flexible and expandable structure

Thanks to its modular architecture, FIM-7L can easily adapt to your growing needs. You can add digital or analog I/O modules and expand the system with special sensors. With a capacity to control up to 64 tanks and 16 pumps, it provides scalable solutions from small stations to large refueling facilities.

Easy installation and full equipment

The product comes standard with a wall-mounting bracket and power cable. Its compact design allows for easy installation inside panels or directly on walls. The durable metal body ensures long-lasting and safe operation.

Application areas

Fuel station pump and tank management

AdBlue filling facilities

Construction sites and fleet fuel management

Public institutions and private refueling centers

Centralized tank monitoring systems

Why FIM-7L?

FIM-7L is a reliable solution entirely developed with local production and FIMTEK engineering. With its flexible communication infrastructure, intuitive touchscreen, remote access, and alarm management, it allows you to control all your field operations from a single device.

With FIM-7L, achieve maximum efficiency, minimum downtime, and complete control in your operations.